CNC Milling

CNC milling is a computer-controlled process that involves using cutting tools to remove a portion of the workpiece. Its basic setup includes a workbench and cutting tools attached to the spindle. The workpiece is placed on the workbench of the machine, while the cutting tool rotates to shape the workpiece. The rotation of the cutting tool will depend on the type and complexity of the CNC milling machine. CNC milling has a wide range of applications and can be used for various materials, including metal, plastic, wood, and glass. The production capacity of CNC milling is most suitable for batch processing. Enterprises that can produce small batches of parts in a single run provide equipment. Our CNC milling services provide our customers with the advantages of processing multifunctional and complex shaped products. Create various customized products for customers to meet their unique needs.... VIEW MORE +

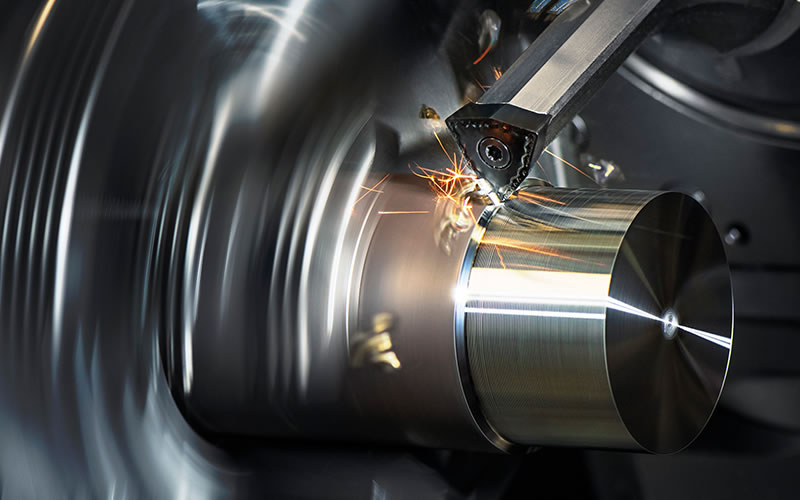

CNC turning

CNC turning is a manufacturing process in which a material rod is fixed in a chuck and rotated, while tools are fed into the workpiece to remove the material and form the desired shape. It can produce small and large batches of components. Not only can it process any pitch straight, conical, metric, inch, and end face threads, but it can also process increased pitch, reduced pitch, and threads that require smooth transitions between equal pitch and betrayal pitches. The shape accuracy of ultra precision machining can reach 0.1 μ m. Appearance roughness reaches 0.02 μ m Our CNC lathe has high machining accuracy, stable and reliable machining quality, strong adaptability, and good flexibility, Capable of providing customers with parts with particularly complex machining contours or difficult to control dimensions, such as metal parts, mold parts, shell parts, etc. We customize our products according to the unique requirements of each industry customer, making them more intelligent and user-friendly, while helping customers reduce costs and improve efficiency.... VIEW MORE +

Sheet Metal

Metal sheet metal processing is called sheet metal processing. For example, using sheet metal to make chimneys, iron barrels, oil tanks, ventilation pipes, elbows, small ends, Tianyuan places, funnel-shaped structures, etc. The main processes include cutting, bending, forming, welding, riveting, etc. Sheet metal parts are sheet metal hardware parts that can be processed through stamping, bending, stretching, and other methods. A general definition is a part whose thickness remains unchanged during the processing. Sheet metal processing includes traditional methods and process parameters such as cutting and cutting, stamping and bending, as well as various cold stamping mold structures and process parameters, working principles and operating methods of various equipment, as well as new stamping technologies and processes. Our sheet metal processing can provide customers with suitable production for small batches and multiple varieties, and the quality of finished products. The quality of stamped parts is very good, not only do they have high precision and flatness, but they also make the product consistent.... VIEW MORE +

Laser Welding

Laser cutting: Using a high-power density laser beam to irradiate the material being cut, high-energy laser pulses locally heat the material in small areas, and the energy radiated by the laser diffuses through the internal diffusion of the material through heat transfer, melting the material and forming a specific molten pool. Simultaneously, compressed gas coaxial with the laser beam is used to blow away the melted material, causing the laser beam to move relative to the material along a certain trajectory, thereby forming a certain shape of slit. It is a new type of welding method mainly aimed at welding thin-walled materials and precision parts, which can achieve spot welding, butt welding, overlap welding, seal welding, etc. Laser cutting technology is widely used in the processing of metal and non-metallic materials. Our laser cutting can achieve high-quality processing, shorten processing time, improve processing efficiency, reduce processing costs, and improve workpiece quality. Provide customers with fast, efficient, and high-quality services.... VIEW MORE +

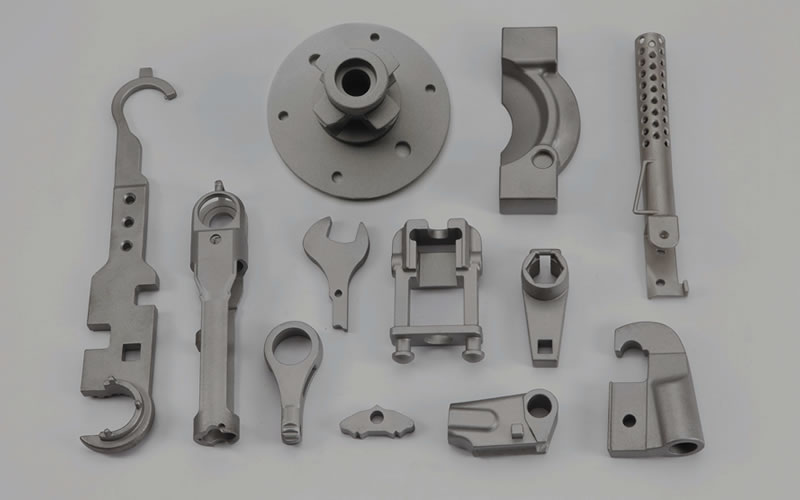

Precision Casting

Precision casting is one of the casting methods. Compared with traditional casting processes, precision casting is a special casting method. It can obtain relatively accurate shapes and high casting accuracy. The use of precision casting can save valuable materials and cutting time, reduce the weight of the blank, and improve product performance. Not limited by the size, thickness, and complexity of castings, the production method is convenient. Our precision casting has high dimensional accuracy and surface finish, which can not only achieve mass production and ensure the consistency of castings, but also avoid residual tool marks after processing. Parts that can meet a small amount of demand only require a small amount of machining allowance, according to product needs or heat treatment and cold processing.... VIEW MORE +

Die-casting

Die casting is a metal casting process that utilizes the inner cavity of the mold to apply high pressure to the melted metal. Molds are usually made from alloys with higher strength, and this process is somewhat similar to injection molding. Widely used and widely used: common die-cast automotive parts, die-cast automotive engine parts, die-cast air conditioning parts, die-cast gasoline engine cylinder heads, die-cast valve rocker arms, die-cast valve supports, die-cast decorative parts, die-cast guardrail parts, die-cast wheels, and other parts. Die casting has the following three advantages: good product quality, high dimensional accuracy of castings, generally equivalent to 6-7 levels, and even up to 4 levels; Good surface finish, generally equivalent to 5-8 grades; The strength and hardness are relatively high, and the strength is generally increased by 25-30% compared to sand casting, but the elongation is reduced by about 70%; Stable size and good interchangeability; Can be used for die-casting thin-walled and complex castings. We can provide customers with services with high production efficiency and machine productivity, precise size of produced die castings, and smooth surfaces. Generally, it is used directly without mechanical processing, or the processing volume is very small, which not only improves the metal utilization rate, but also saves assembly time and metal.... VIEW MORE +

Precision forging

Precision forging is an advanced forging method that improves the accuracy of forgings and reduces surface roughness. The advantage of this method is that it reduces the machining allowance and dimensional tolerance of the forging, and can make the forging size as close to or equal to the part size as possible. Refined blanks use precision forging technology to replace rough machining processes, and precision forgings are directly processed to obtain finished parts. The dimensional accuracy of cold precision forging can reach 0.02-0.05mm. Due to its high-quality, efficient, and low energy consumption characteristics Typical applications of precision forging include steam turbine blades, straight bevel gears, toothed parts, etc. When using the precision die forging method to manufacture bevel gears, the tooth shape part is directly forged, and only a small amount of grinding is required for the tooth shape part to be used. Due to the reasonable fiber orientation, the service life is greatly improved. The most obvious characteristics of precision forging are high material utilization rate, high dimensional accuracy, and low surface roughness. We can provide customers with accessories such as discs, shafts, complex structural components, and blades for applications.... VIEW MORE +

Surface Treatment

By using some physical, chemical, mechanical, or composite methods to make the metal surface have a different organizational structure, chemical composition, and physical state from the matrix, thereby enabling the treated surface to have different properties from the matrix. A method used to improve the surface condition and mechanical, physical, or chemical properties of a workpiece. Generally, products manufactured by mechanical processing methods such as casting require further cleaning, hardening, grinding, polishing, painting, or electroplating on all or part of their surfaces to enhance their various characteristics, smoothness, and aesthetics. effect: 1. Increase the mechanical properties such as surface hardness, wear resistance, and fatigue resistance, and apply them to molds, pistons, cylinders, tool machines, slides, shafts, gears, etc. 2. Improve surface roughness and friction, apply to sliding surfaces of mechanical components, shafts and bearings, cutting tools, tools, etc. 3. Change the surface's reflection of light, selective absorption, weather resistance and other characteristics, and apply them to mirrors, automotive and locomotive parts, etc.... VIEW MORE +

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.